The highly efficient catalytic removal of VOCs

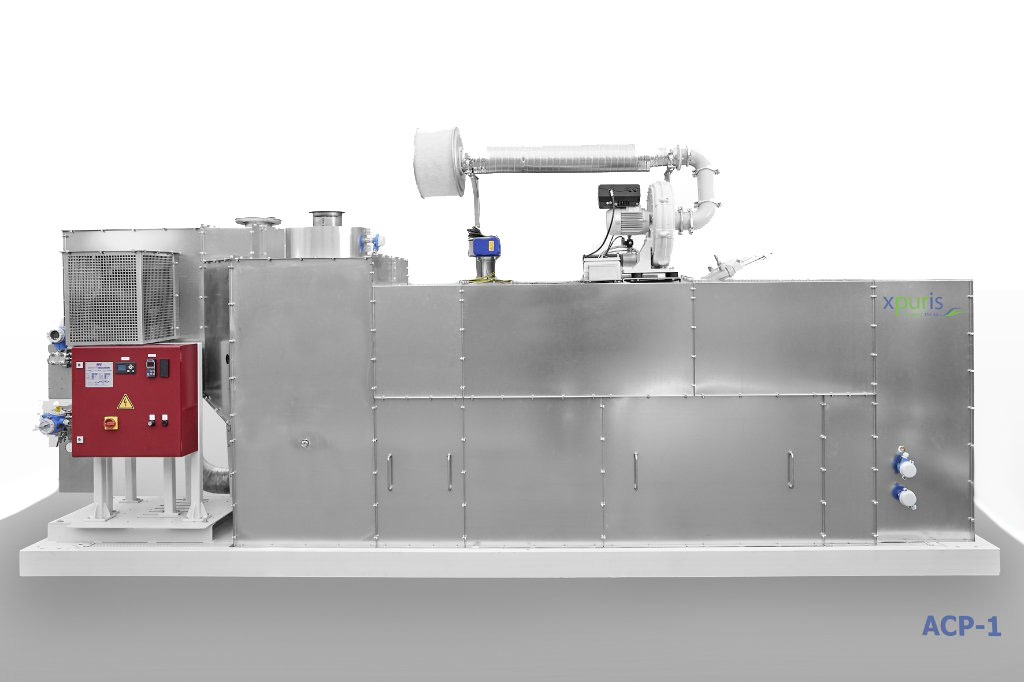

The ACP process is the XPURIS recuperative combustion process for catalytic removal of VOCs. Our compact design of the ACP unit allows for pre-assembly in a space-saving container and testing it in our workshop before shipment.

Each XPURIS ACP unit is equipped with a premium catalyst selected for the individual project to meet the required performance.

With XPURIS ACP Technology you will get access to a dual-function catalyst which removes amines, ammonia, and organic compounds in ONE STEP in case your off-gas contains such components. Your worries disappear as well as do your pollutants without generating secondary pollutants, such as NOx.

The off-gas from the production enters a heat exchanger where it is preheated to around 300°C by heat exchange with the out-going, cleaned air. Then the preheated off-gas is heated to the required inlet temperature by a gas burner or alternatively an electrical heater before the off-gas enters the catalytic reactor. Here the catalytic cleaning occurs, and the clean air exits through the heat exchanger where it gives off the heat, before the clean air is led to the stack.

A simple process flow diagram is shown below.

To view the product video, please hover your mouse over the graphic: