The xpuris ACP process is the recuperative oxidation process for the catalytic removal of volatile organic compounds (VOC). The compact design of the ACP exhaust air purification system allows space-saving delivery of pre-assembled modules that have already been extensively tested in our production facility.

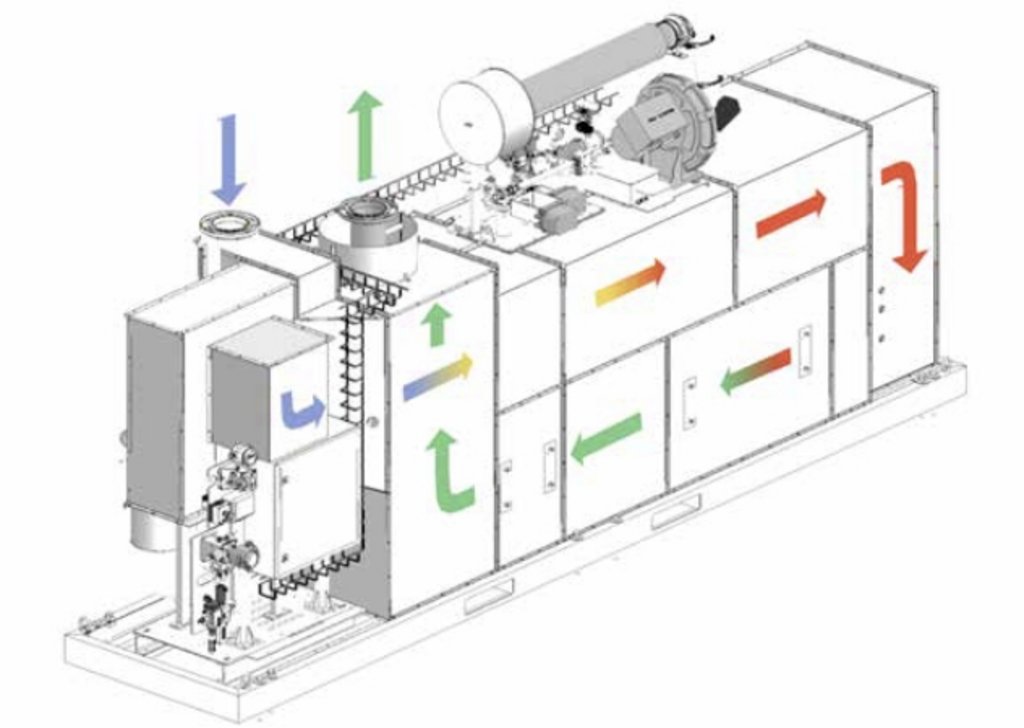

Drawn in via the integrated fan and directed over a heat recovery unit, the exhaust gas from production is preheated with the hot clean gas from the ACP. This preheated exhaust gas is then heated further to the required inlet temperature with the aid of a - preferably electric - heater before it enters the catalytic converter. In this process step, the actual catalytic cleaning takes place. The catalytic converter usually consists of precious metals, metal oxides or combinations, which accelerate the oxidation of the pollutants and allow them to run off completely at significantly lower temperatures. This leads to a significant increase in energy efficiency compared to pure combustion systems. The temperature required for oxidation is largely determined by the composition of the ingredients and the clean gas limits to be complied with. At the end of the process, the purified exhaust air is discharged into the open air via the heat recovery unit. The existing waste heat from the process is used to preheat the cold raw gas, which contributes to a further improvement in energy efficiency.

Customization based on pre-developed standard designs - all our equipment is tailored to your exact requirements. We work closely with our customers to ensure that we fully understand their processes before offering a customized solution.

-

XPURIS ACP 0.1

APPLICATION RANGE:

• Exhaust air volume flow 50 - 100 Nm³/h • Reduzierung der Abluftemissionen von Gesamt-C, Aminen, Formaldehyd, Phenol u.v.m.

• Reduction of exhaust air emissions of total C, amines, formaldehyde, phenol, etc.

• Raw gas temperature 20 - 60°C

• Outdoor installationTECHNICAL DATA:

• Dimensions (4.8 m x 1.7 m x 2.5 m)

• Operating power current 5 - 15 kW -

XPURIS ACP 1

APPLICATION RANGE:

• Exhaust air volume flow 500 - 1,500 Nm³/h

• Reduction of exhaust air emissions of total C, amines, formaldehyde, phenol, etc.

• Raw gas temperature < 160°CTECHNICAL DATA:

• Dimensions (5.2 m x 1.1 m x 2.3 m)

• Operating capacity heating 10 - 70 kW

• Operating power electricity 2 - 5 kW

• Heat recovery up to 70% -

XPURIS ACP 4

APPLICATION RANGE:

• Exhaust air volume flow 2,400 - 5,600 Nm³/h

• Reduction of exhaust air emissions of total C, amines, formaldehyde, phenol, etc.

• Raw gas temperature < 160°CTECHNICAL DATA:

• Dimensions (7.8 m x 2.8 m x 2.1 m)

• Operating capacity heating 20 - 240 kW

• Operating power electricity 8 - 30 kW

• Heat recovery up to 70 %