xpuris solutions for sustainable exhaust air purification in paint processing companies

PAINTING AND COATING

We remove odors and VOCs from the exhaust air of the paint industry - ecologically and economically.

XPURIS EXHAUST AIR PURIFICATION FOR INDUSTRIAL COATING

Basically, there are two different coating processes: Liquid coating and powder coating. In addition to the refinement and visual change, the coated surfaces also gain far more resistance to external influences. Water-based or solvent-based paints are used, and applied manually or by machine. In this process, more or less automated and complex systems and machines are used.

Solvent-based paints are much easier to process and guarantee a smooth, glossy surface and a particularly high level of quality precisely due to the solvents they contain. A by-product of processing solvent-based paints are VOCs (volatile organic compounds). These can be effectively and sustainably removed from the exhaust air using an xpuris cleaning system.

WE UNDERSTAND YOUR REQUIREMENTS

In our portfolio you will find innovative and energy-saving systems for exhaust air purification that are tailored precisely to your company's needs. So nothing gets in the way of sustainable air pollution control.

THE IDEAL SOLUTION

FOR YOUR PAINTING AND COATING

-

METAL COATING

Coating metal surfaces can achieve great visual effects. In addition to this aesthetic aspect, protection against atmospheric and chemical influences, which can lead to rust, oxidation or other undesirable reactions, plays a more important role. The resulting VOCs can be effectively removed from the exhaust air using ACP catalytic oxidation. For larger volume flows, concentration in the zeolite wheel AWP is also suitable. -

PLASTIC COATING

Depending on the composition, nature and type of base, the painting of plastics requires different primers based on different substances. This ensures maximum adhesion of the applied paint film. In order to clean the VOCs produced from the exhaust air, we recommend the catalytic oxidation ACP, for larger volume flows together with the zeolite wheel AWP for concentration. -

WOOD VARNISHING

Varnished wood is optimally protected against the elements, UV radiation, moisture and pests. To ensure the environment is also perfectly protected from the VOCs produced during painting, these can be removed from the exhaust air with our catalytic oxidation ACP. If the exhaust air from your production has larger volume flows, we recommend concentration with the AWP zeolite wheel. -

PAPER FINISHING

Finishing with a coating gives paper a completely new look and feel. The previously porous surface can be given gloss, structure or other effects. In order to efficiently control the resulting VOC emissions, the catalytic oxidation ACP can be used and, for concentrating larger volume flows, the zeolite wheel AWP in addition. -

GLASS COATING

Coating glass is primarily for aesthetic reasons - infinite color variations and effects are possible - but of course also offers additional protection for example against UV radiation. Effective protection against VOC emissions is provided by purifying the exhaust air using ACP catalytic oxidation, in combination with the zeolite wheel AWP for larger volume flows. -

DIP COATING

Special shapes and geometries are sometimes difficult or impossible to reach using conventional spraying processes. If a coating of the surface is nevertheless necessary, the dip coating process is used. Also necessary is the exhaust air purification of VOCs by e.g. catalytic oxidation ACP, for larger volume flows in combination with the zeolite wheel AWP for concentration. -

TEXTILE COATING

Textile coating refers to the application of a visible synthetic layer to a textile substrate. The aim is to change the physical properties of the fabric, such as waterproofness, mechanical strength, chemical resistance, light stability, permeability and abrasion resistance, as well as the design, look and feel. To change and efficiently reduce VOC emissions in the exhaust air, you can use ACP catalytic oxidation, if necessary in combination with the zeolite wheel AWP to concentrate larger volume flows. -

COIL COATING

The continuous process for coating one or both sides of steel or aluminum sheets creates a composite material consisting of a metal substrate and an organic coating. The catalytic oxidation ACP efficiently removes organic substances such as VOCs from the exhaust air. For larger volume flows, the AWP zeolite wheel is additionally used for concentration. -

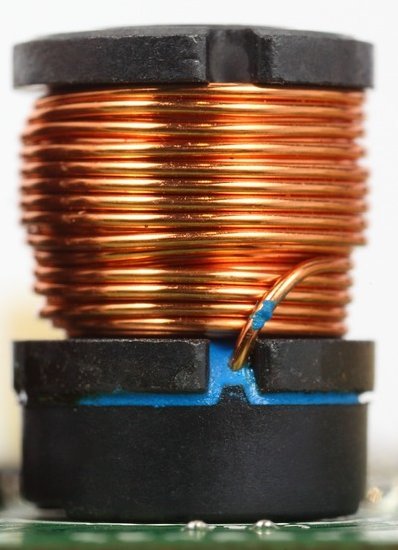

CABLE COATING

Copper wire is coated in several layers with insulating varnish. The enamel consists of resins dissolved in solvents, various additives and curing catalysts. To prevent unwanted substances such as VOCs from being released into the environment with the exhaust air, the catalytic oxidation ACP cleans the air thoroughly and effectively. The zeolite wheel AWP is used to concentrate larger exhaust air flows. -

COATING METAL CANS

Most food cans are coated with synthetic material on the inside. This prevents direct contact between food and metal and thus corrosion of the metal. Furthermore, no metal ions can get into the food. To ensure that no VOCs are released into the environment through the exhaust air, ACP catalytic oxidation is an option, for larger volume flows in combination with the zeolite wheel AWP.

EVERYTHING FROM A SINGLE SOURCE

ENGINEERING &

SYSTEMS:

- Customized and turnkey systems

- Comprehensive advice, design and project planning

- After sales and services

CATALYSTS &

ACTIVE MATERIALS:

- Catalysts, tailored for every application

- Customized solutions, also in dual function

- Analysis and consulting

- Expertise and development

TESTS &

MEASUREMENT SERVICES:

- Comprehensive and tested measuring equipment

- Highly qualified employees

- In-house test facilities for evaluating your purification task

- Network of partner companies for special tasks

YOU HAVE QUESTIONS?

WE ARE HAPPY TO ANSWER THEM!

Our professional employees have decades of experience in development, design, production and service in a wide range of industries.

We attach great importance to detailed, individual and competent consultancy.