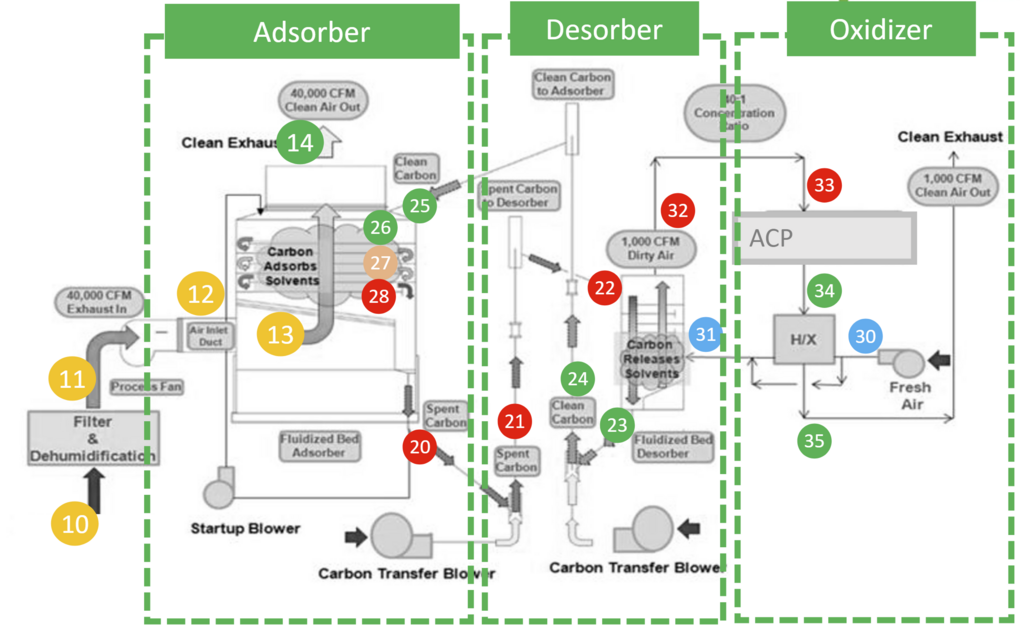

The FBP process is a well-established, highly efficient method for concentrating and cleaning large exhaust gas flows. It offers very high efficiency and therefore comparatively low energy consumption. The process is particularly suitable for applications with high volume flows and low VOC concentrations and consists of three main steps.

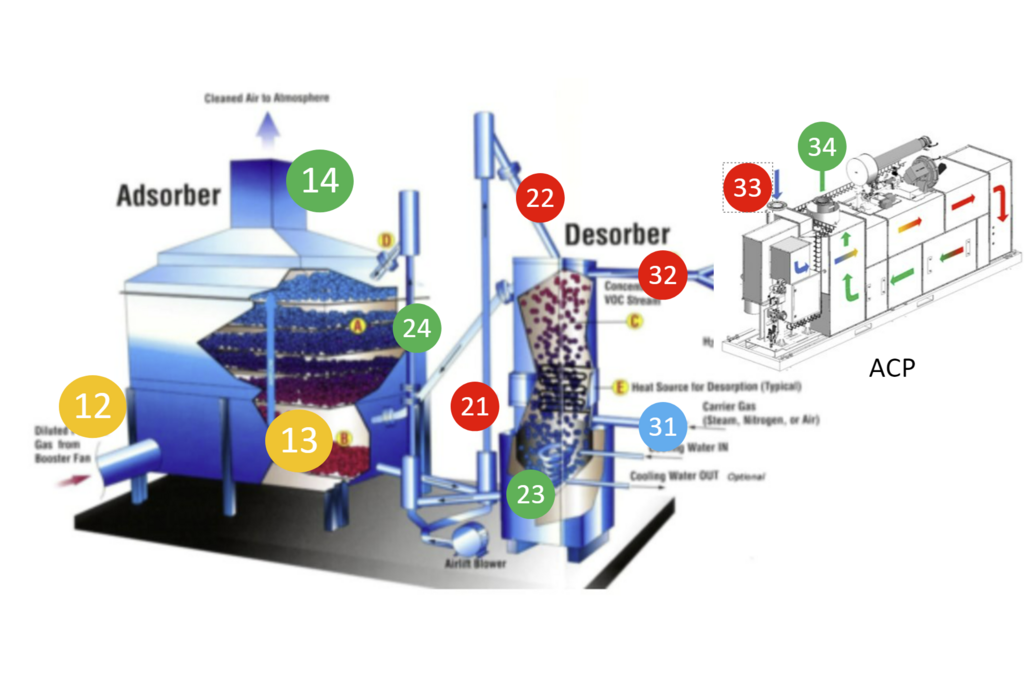

ADSORPTION

The contaminated air flows over a fluidized bed of special activated carbon, which absorbs the pollutants at relatively low temperatures. This purifies the main air flow directly.

DESORPTION

The activated carbon is cleaned in a separate station with hot fresh air, which absorbs the pollutants. This highly contaminated air then flows into the downstream ACP cleaning system.

OXIDATION

The concentrated exhaust gas is completely purified in the catalytic ACP oxidation process. The heat energy generated is recovered and the purified exhaust air is fed back into the clean main air flow.

1. Adsorption

- Contaminated process exhaust air is initially dedusted and dehumidified

- The exhaust air is then passed over the adsorber fluidized beds using the counterflow principle

- The pollutants are removed from the air and stored in the carbon bed

- The purified, clean air leaves the FBP through the chimney

2. Desorption

- In the desorber, clean air is heated to the required desorption temperature of 200°

- This air adsorbs the pollutants from the special carbon and thus cleans it back to almost new condition

- To completely clean the activated carbon again, there is a special cycle at significantly higher temperatures

- Depending on the application, this should be repeated regularly on a weekly to monthly basis

- The small, highly contaminated secondary air flow transports the pollutants into the catalytic cleaning system ACP

3. Oxidation

- The hot, VOC-contaminated air enters the ACP oxidation process

- This is where the catalytic oxidation of the pollutants takes place

- In the heat exchanger a large part of the energy used is recovered

- The cooled and clean air flow exits the ACP and is fed back into the main air flow

Customization based on pre-developed standard designs - all our equipment is tailored to your exact requirements. We work closely with our customers to ensure that we fully understand their processes before offering a customized solution.

-

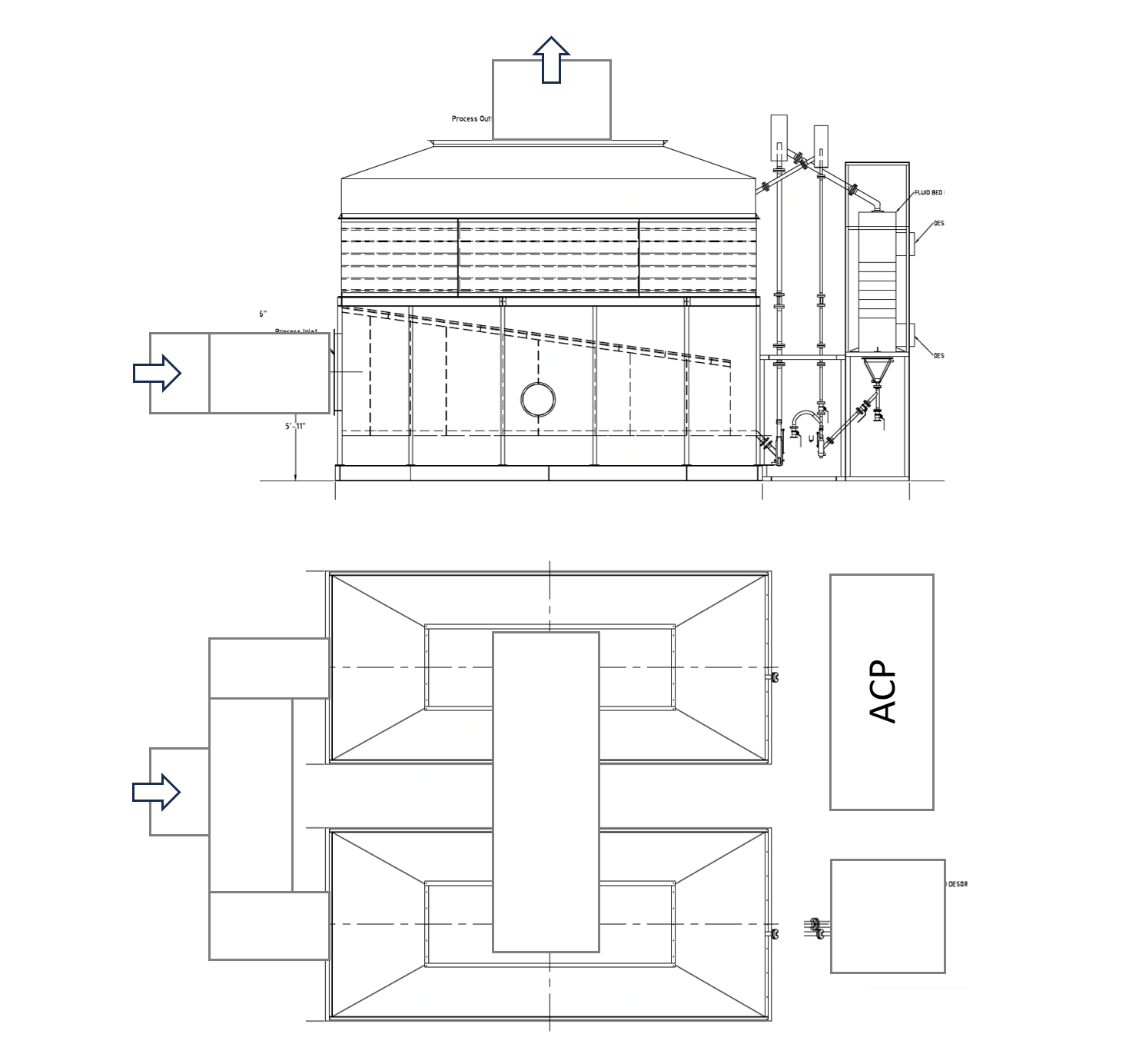

XPURIS FBP 140

APPLICATION RANGE:

• Exhaust air volume flow up to 140,000 Nm³/h

• Reduction of exhaust air emissions of total C and odor

• Raw gas temperature < 50°C

• Outdoor installationTECHNICAL DATA:

• Dimensions (20.0 m x 10.0 m x 5.0 m)

• Operating power current 10 - 100 kW