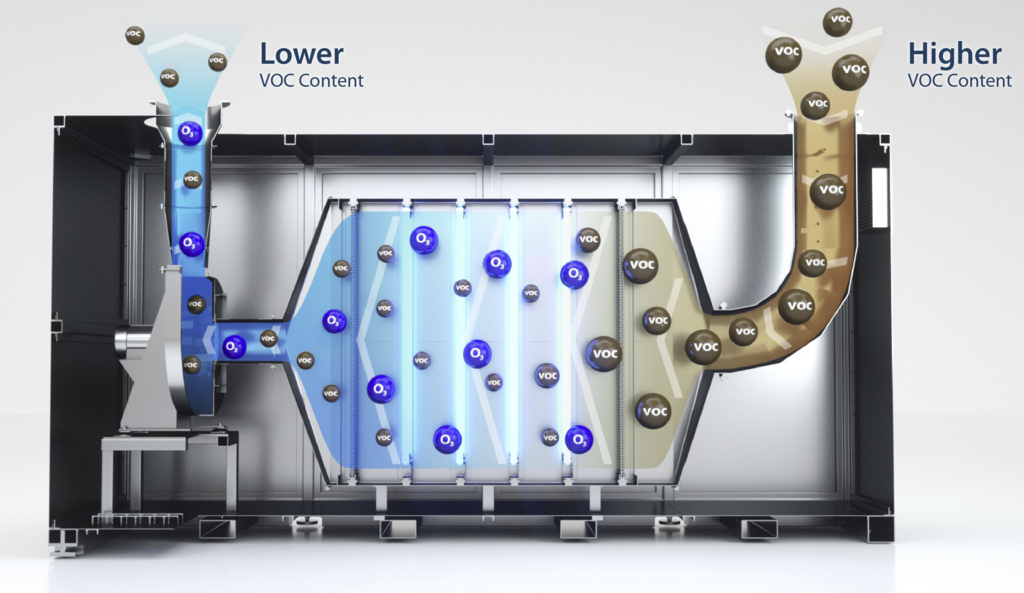

In the UVP process, the exhaust gas to be cleaned is passed through a chamber with special UV emitters at low temperatures. The special wavelength of these emitters causes the substances present in the air to be converted into highly reactive radicals. These in turn react with the pollutants and volatile organic compounds (VOC) in the air flow and break them down below the limit value.

Ultra-violet purifier systems are particularly suitable for operations with large air volumes and low levels of pollutants. They work at low operating temperatures and are therefore very energy-efficient. Automatically integrated cleaning systems ensure uninterrupted operation over long periods of time. The systems have a compact, modular design and can be individually combined. This makes them flexible and adaptable to a wide range of requirements. xpuris UVP systems can be installed both centrally and decentrally.

Especially for the removal of odors from exhaust air, UVP systems are preferably used. These systems run exclusively on electricity and do not require fossil fuels. This makes them an environmentally friendly and cost-effective solution.

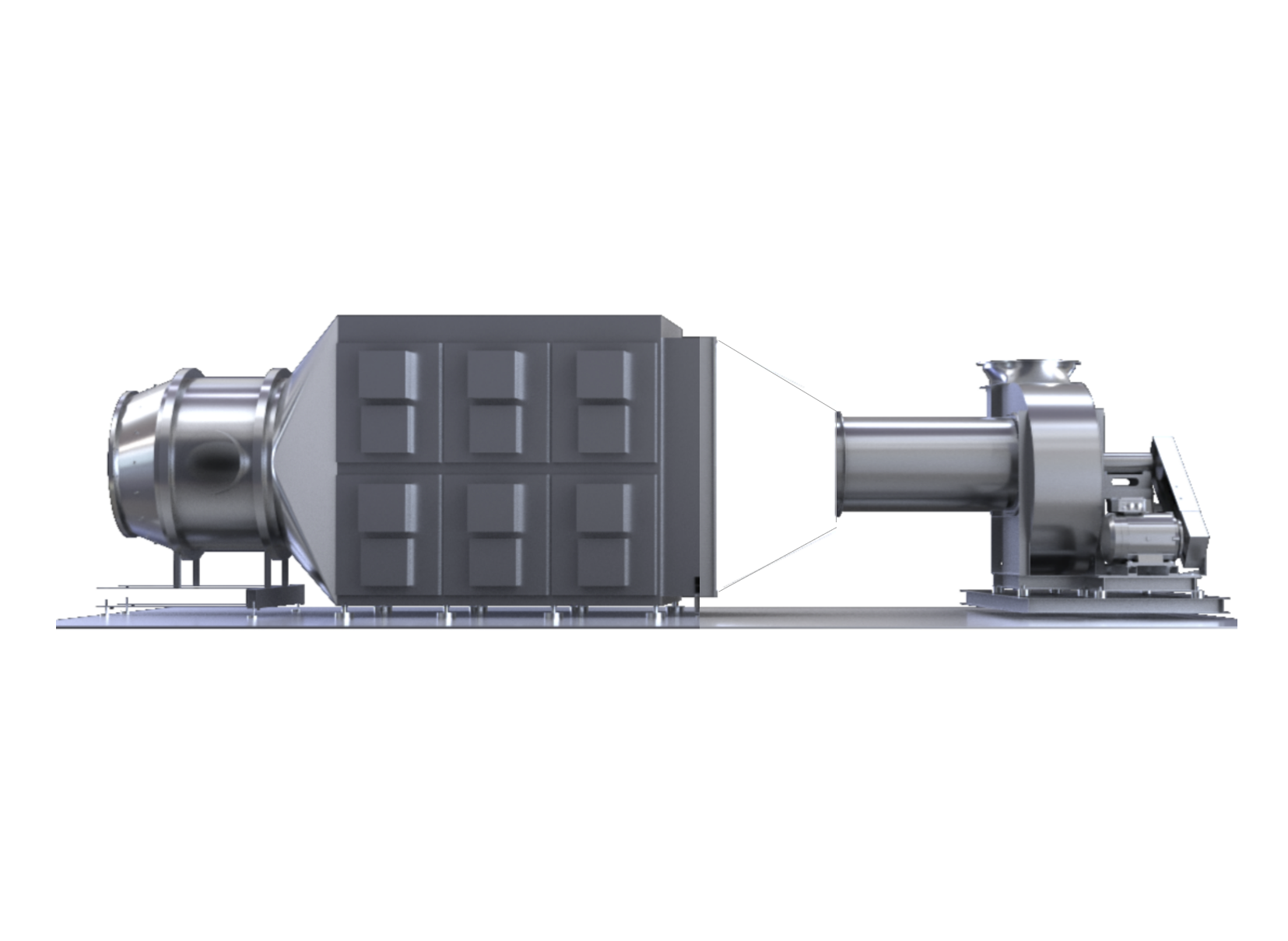

Customization based on pre-developed standard designs - all our equipment is tailored to your exact requirements. We work closely with our customers to ensure that we fully understand their processes before offering a customized solution.

-

XPURIS UVP 3

AREA OF APPLICATION:

• Exhaust air volume flow 500 - 4,000 Nm³/h

• Reduction of exhaust air emissions of total C and odor

• Exhaust air temperature up to 100°CTECHNICAL DATA:

• Dimensions (4.5 m x 1.7 m x 2.3 m)

• Operating power current 1 - 15 kW

• Pressure loss 300Pa

-

XPURIS UVP 10

APPLICATION RANGE:

• Exhaust air volume flow 1,000 - 12,000 Nm³/h

• Reduction of exhaust air emissions of total C and odor

• Exhaust air temperature up to 100°CTECHNICAL DATA:

• Dimensions (1.0 m x 1.0 m x 1.6 m)

• Operating power current 1 - 15 kW

• Pressure loss 100 Pa -

XPURIS UVP 20

AREA OF APPLICATION:

• Exhaust air volume flow 10,000 - 25,000 Nm³/

• Reduction of exhaust air emissions of total C and odor

• Exhaust air temperature up to 100°CTECHNICAL DATA:

• Dimensions (10.0 m x 2.0 m x 1.6 m)

• Operating power Current 10 - 75 kW

• Pressure loss 300Pa