Catalytic oxidation effectively removes harmful substances and compounds from almost all exhaust gas streams at relatively low temperatures. Due to the low operating temperature, a catalytic converter significantly reduces energy consumption and therefore reduces the environmental impact even further.

The exhaust gas from the production process is first drawn in via the integrated fan, passed through a heat recovery unit and preheated with the hot clean gas from the ACP. This preheated exhaust gas is then heated further to the required inlet temperature with the aid of a preferably electric heater before it enters the catalytic converter.

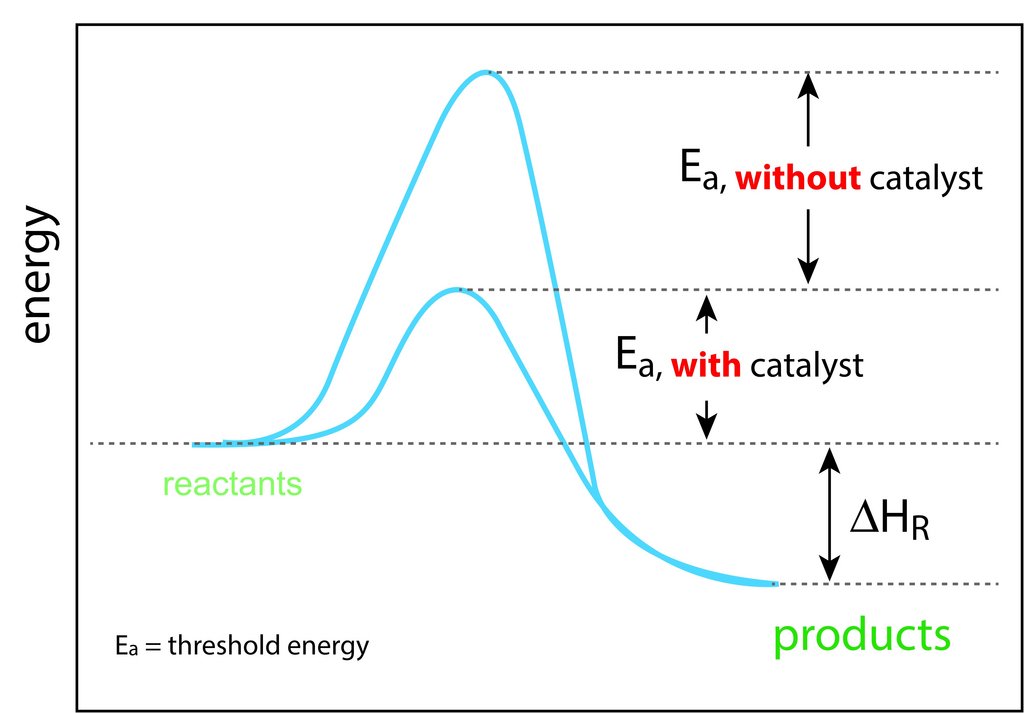

The required temperature depends mainly on the substances to be decomposed. The catalyst usually consists of precious metals or metal oxides, which accelerate the oxidation of the pollutants and allow them to completely decompose at lower temperatures. This leads to significantly higher energy efficiency.

Finally, the purified exhaust air is led outside via the heat recovery unit. The waste heat recovered in the process is used further in the cycle and serves to preheat the cold raw gas. This contributes to a further improvement in energy efficiency.

Customization based on pre-developed standard designs - all our equipment is tailored to your exact requirements. We work closely with our customers to ensure that we fully understand their processes before offering a customized solution.

xpuris catalysts and adsorbents

-

Catalysts for the removal of volatile organic compounds (VOC)

Catalytic oxidation is widely considered to be the most effective method of reducing VOC emissions.

The xpuriCAT Oxi catalyst series enables catalytic combustion at lower temperatures, reducing operating costs and minimizing thermal and mechanical stress on equipment. This process includes the oxidation of CO and various hydrocarbons - such as formaldehyde, aldehydes, PAHs, NMHCs, VOCs and TOCs - to harmless CO2 and water.

Our catalyst solution:

xpuriCAT Oxi

-

Purification of technical gases

The xpuriCAT Pure catalyst series is used for gas purification of trace pollutants, including VOCs, O2 and H2. These catalysts are effective in purifying a range of technical gases such as methane (CH4), argon (Ar), helium (He), nitrogen (N2), oxygen (O2), hydrogen (H2) and carbon dioxide (CO2). xpuriCAT Pure catalysts are ideal for industries that require deoxygenation (DeOxo) and general gas purification, such as electrolysis, biogas, pipeline gas, beverages, landfills and semiconductor manufacturing.

Our catalyst solution:

xpuriCAT Pure

-

Removal of nitrous oxide (N2O) and ammonia (NH3)

The removal of gaseous ammonia NH3 or nitrous oxide N2O is no easy task. Nitrous oxide is a powerful greenhouse gas with a global warming potential almost 300 times that of CO2. Our N2O degradation catalysts offer a cost-effective solution that is significantly lower than standard CO2 prices. The removal of gaseous ammonia is a tricky business, where our catalyst offers extremely high efficiency combined with high selectivity for harmless nitrogen (N2).

Our catalyst solution:

xpuriCAT N-Red

-

Removal of siloxanes

The xpuriSORB adsorbent has been developed to protect downstream processes and equipment from the negative effects of organic silicon species such as silanes and siloxanes. These compounds can quickly damage motors, valves and catalysts, leading to costly repairs and downtime. xpuriSORB offers an efficient and reliable solution to protect your machines and ensure optimal performance and long service life.

Our catalyst solution:

xpuriSORB

-

Removal of other harmful components

xpuris supports companies and industries in eliminating harmful exhaust emissions and complying with strict regional regulations. Our customizable solutions remove hydrocarbons, odors, CFC gases, halogens and other compounds that affect air quality. With decades of industry experience, xpuris offers sustainable exhaust gas purification technology to treat industrial waste gases. Contact our specialists for customized solutions that provide cleaner and safer air.

Our experts have extensive know-how and decades of experience in catalytics,

especially on catalysts and adsorbers for use in VOC oxidation applications. We provide you with the right advice, support and measurement services if you require them. We develop solutions that are precisely tailored to your needs.

Some of our xpuriCAT catalysts can simultaneously fulfill several functions within one process stage and offer you as a customer considerable economic advantages.