Ecological and economical solutions for exhaust air purification in foundries

FOUNDRY INDUSTRY

xpuris solutions remove odors, s, amines, formaldehyde, benzene, phenol, methyl formate, tetrathyl silicate and other substances from the exhaust air.

XPURIS EXAUST AIR PURIFICATION FOR FOUNDRIES

Metal foundries primarily work with aluminum and cast iron. Besides these, other metals such as steel, magnesium, copper, tin and zinc are also used. The casting process typically results in the emission of odorous and hazardous gases, which originate in the various sectors:

- Melting stores, especially cupola furnaces, but also induction furnaces

- Molding shops - during the casting and mold cooling phase

- Core production

- Core hardening furnaces

- Sand recovery

- Die casting with metal molds in aluminum foundries

They all have in common that xpuris exhaust air purification systems sustainably remove all the emerging odors, VOCs (volatile organic compounds) and other harmful and polluting substances from the exhaust air.

WE UNDERSTAND YOUR REQUIREMENTS

In our portfolio you will find innovative and energy-saving systems for exhaust air purification that are tailored precisely to your company's needs. So nothing gets in the way of sustainable air pollution control.

THE IDEAL SOLUTION

FOR YOUR FOUNDRY

-

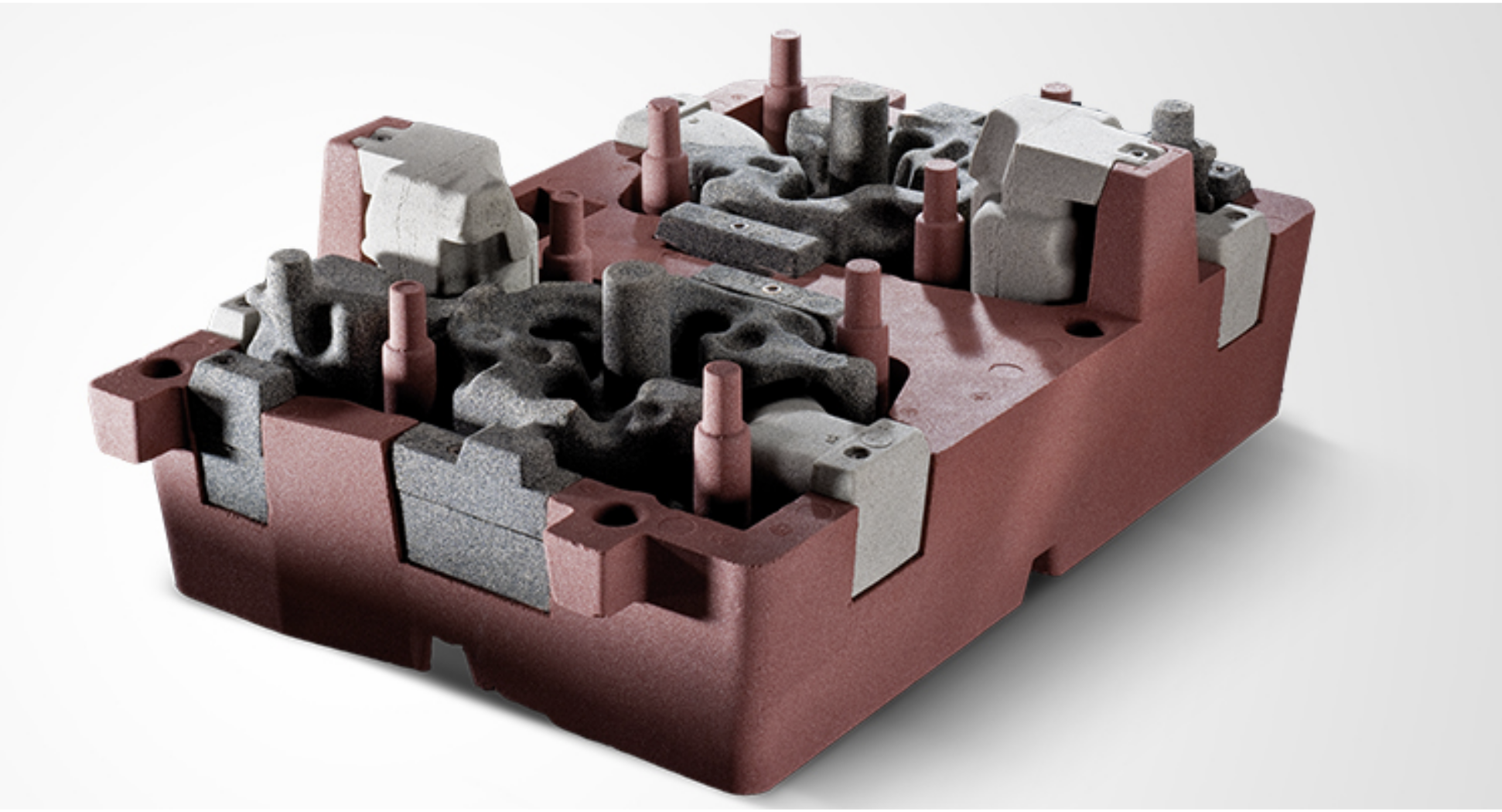

CORE PRODUCTION

The first step in the production of cast elements is the production of a suitable core, which is used in the next step to create the cavity for casting. Depending on the requirements of the casting to be produced, different types of sand can be used. These are heated or solidified into a core using the so-called cold box process. Especially for the cold box process, gassing and disposal devices are of great importance. The pollutants, VOCs and dust released here can be sustainably purified from the exhaust air using the ACP catalytic oxidation process and the UVP system. gereinigt werden. -

CORE DRYING

After the manufacturing process, the cores must be dried or cured. In the cold box process, a catalyst is added to accelerate the curing of the cores produced. In inorganic core production, on the other hand, drying takes place in a complex process using heat and hot air. The waste heat generated in this process can be reused - even externally.In both processes, it is important to clean the exhaust air from dust, VOCs and other pollutants. The ACP process with catalytic oxidation and the UVP system are suitable for this purpose.

-

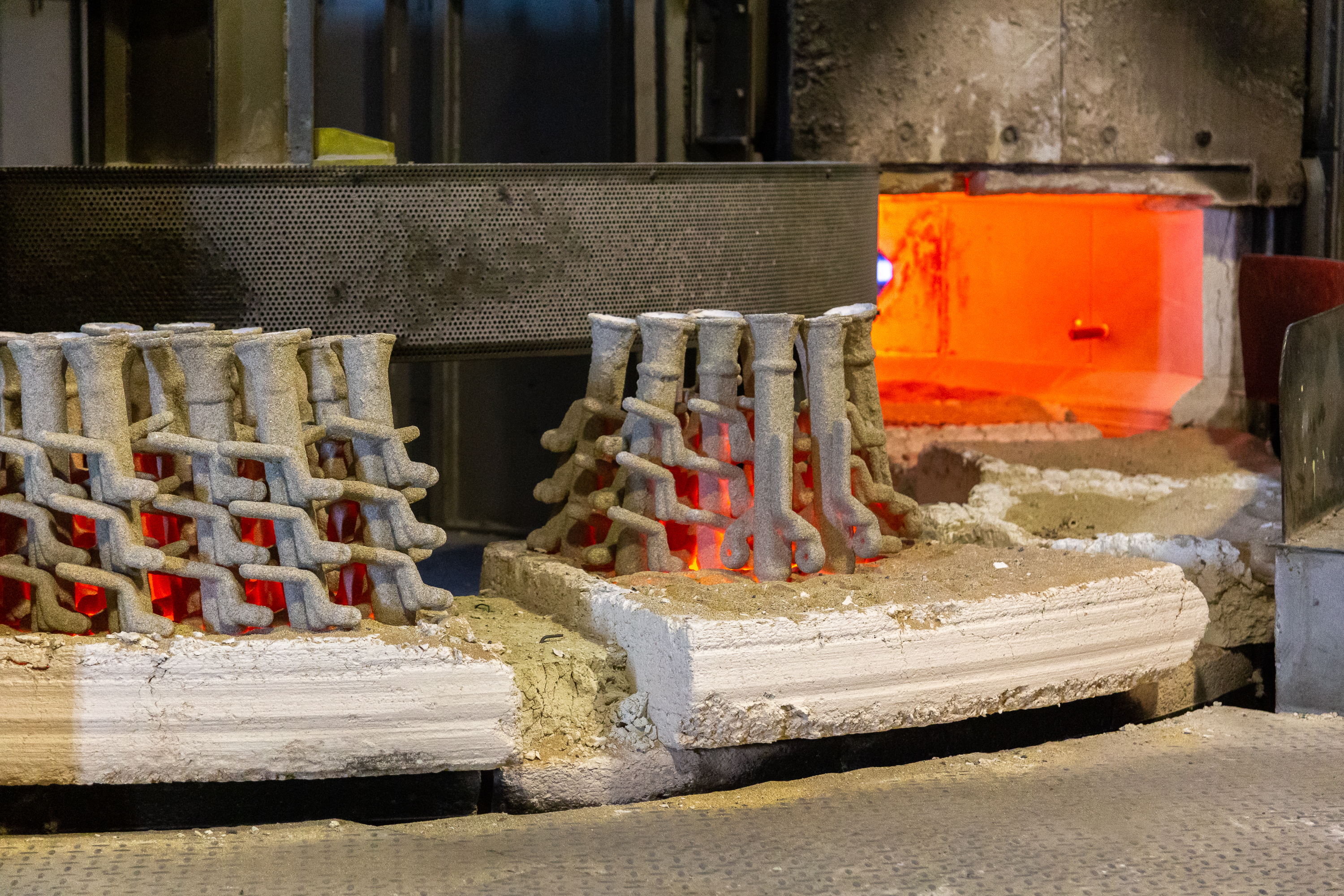

MOLDING / POURING LINE

The mechanical production of casting molds takes place in a casting line, which is part of the molding line. A molding material mixed with special binding agents is compacted around the model or core. Into the resulting mold, the liquid material is then poured. Basically, there are two different types of molding systems: box molding systems and boxless molding systems.What both have in common is that the exhaust air produced in the process can be optimally cleaned of VOCs and other pollutants using the ACP catalytic oxidation and the UVP system.

-

COOLING ZONE / UNPACKING STATION

Another part of the molding line is the cooling zone. Here, the cast molds are initially cooled down to the point where they can be unpacked. The still hot castings then pass through a cooling section in which they are cooled down at a rate suitable for the respective material. This is done either with ambient air or by blowing in cooling air. During this process, dust and VOCs are released into the air, which can be best cleaned from the exhaust air by the catalyze oxidation ACP and the UVP system.

ACP

EVERYTHING FROM A SINGLE SOURCE

ENGINEERING &

SYSTEMES:

- Customized and turnkey systems

- Comprehensive advice, design and project planning

- After sales and services

CATALYSTS &

ACTIVE MATERIALS:

- Catalysts, tailored for every application

- Customized solutions, also in dual function

- Analysis and consulting

- Expertise and development

TESTS &

MEASUREMENT SERVICES:

- Comprehensive and tested measuring equipment

- Highly qualified employees

- In-house test facilities for evaluating your purification task

- Network of partner companies for special tasks

YOU HAVE QUESTIONS?

WE ARE HAPPY TO ANSWER THEM!

Our professional employees have decades of experience in development, design, production and service in a wide range of industries.

We attach great importance to detailed, individual and competent consultancy.